13 November 2024

3D printing technology encompasses transforming a digital 3D design into a solid model with multiple layering. This technology is highly driven due to its ability to rapidly create prototypes which help in design thinking, emphasizing empathy, creativity, and iteration to solve any complex problems.

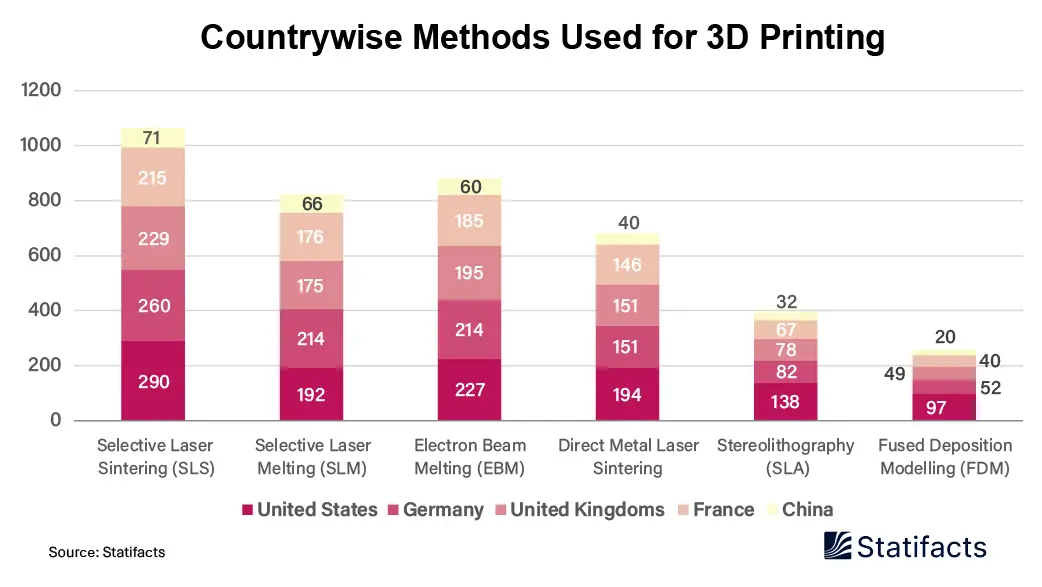

The application of 3D printing is widely noticed in industries such as aerospace, dental, toys, medical, architecture and many more. The United States has the largest number of adoptions of 3D printing methods compared to other countries and the United Kingdom, has the second largest. The U.S. has filed 55.14% of patented in 3D printing in aerospace and only 35.9% patents in aerospace parts and components such as aircraft components (wings, structural components, body), UAVs components (Avionic, flight control, etc), space components, defence weaponry and tooling.

The demand for 3D printing is rising due to its potential to transform the space exploration industry. 3D printing is mainly used by space explorers in case of emergency to produce spares or tools. NASA has established a base of 3D scanners and printers at ISS for astronauts, this initiative has reduced the cost of space exploration and lightens the load of space crafts and stations.

Gwenaëlle Aridon, lead engineer of Airbus Space Assembly says, “The metal 3D printer will bring a new on-orbit manufacturing capabilities, including the possibility to produce load-bearing structural parts that are more resilient than a plastic equivalent. Astronauts will be able to easily manufacture tools such as wrenches or mounting interfaces that connect several parts. The flexibility and rapid availability of 3D printing will improve astronaut's autonomy.”

There are many variations of passages of Lorem Ipsum available, but the majority have suffered alteration in some form

URL TO BE USED AS REFERENCE LINK:

Placeholder content for this accordion, which is intended to demonstrate the .accordion-flush class. This is the first item's

accordion body.

Placeholder content for this accordion, which is intended to demonstrate the .accordion-flush class. This is the second item's

accordion body. Let's imagine this being filled with some actual content.

Placeholder content for this accordion, which is intended to demonstrate the .accordion-flush class. This is the third

item's accordion body. Nothing more exciting happening here in terms of content, but just filling up the space to make it look, at least at

first glance, a bit more representative of how this would look in a real-world application.

Do you still any question?

Feel free to contact us anytime using our contact form or visit our FAQ page.

Your contact to the Infographics Newsroom