19 November 2024

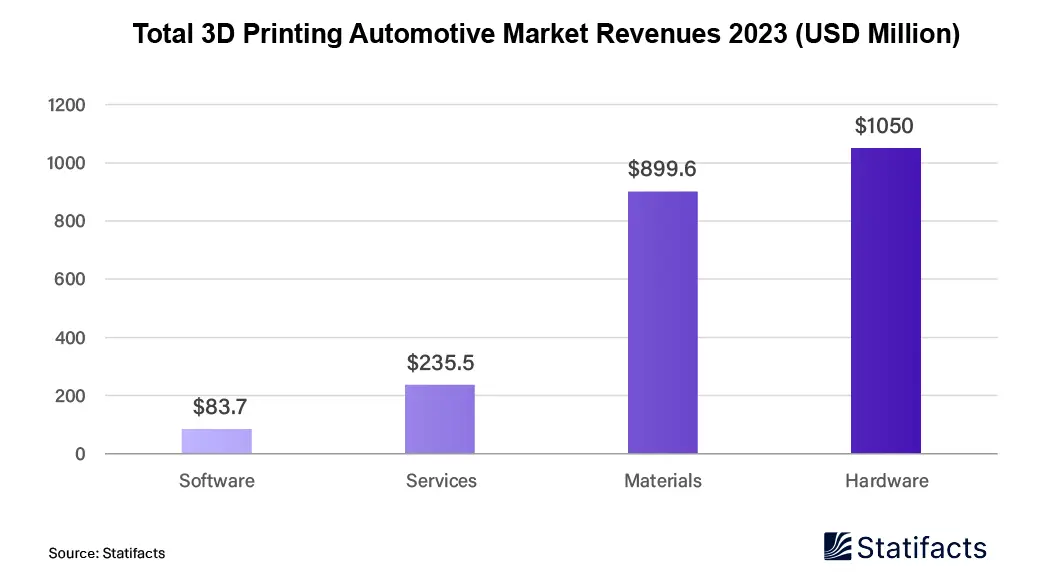

3D printing, also known as additive manufacturing, has revolutionized various industries, including healthcare, aerospace, and consumer goods. Its ability to create complex structures and customized parts with precision and efficiency has garnered significant attention. The automotive industry, always at the forefront of technological innovation, is now exploring the potential of 3D printing to transform manufacturing processes, reduce costs, and enhance vehicle performance.

The use of lightweight materials in 3D printing is a growing trend in the automotive industry. This trend is driven by reducing vehicle weight, improving fuel efficiency, and lowering emissions. In traditional manufacturing processes, such as casting or machining, producing lightweight components can be challenging due to limitations in design and material properties. However, 3D printing allows for the creation of complex geometries and the use of lightweight materials that can meet the structural requirements of automotive parts while reducing weight.

There are many variations of passages of Lorem Ipsum available, but the majority have suffered alteration in some form

URL TO BE USED AS REFERENCE LINK:

Placeholder content for this accordion, which is intended to demonstrate the .accordion-flush class. This is the first item's

accordion body.

Placeholder content for this accordion, which is intended to demonstrate the .accordion-flush class. This is the second item's

accordion body. Let's imagine this being filled with some actual content.

Placeholder content for this accordion, which is intended to demonstrate the .accordion-flush class. This is the third

item's accordion body. Nothing more exciting happening here in terms of content, but just filling up the space to make it look, at least at

first glance, a bit more representative of how this would look in a real-world application.

Do you still any question?

Feel free to contact us anytime using our contact form or visit our FAQ page.

Your contact to the Infographics Newsroom